Graphites for Electrical Discharge Machining (EDM)

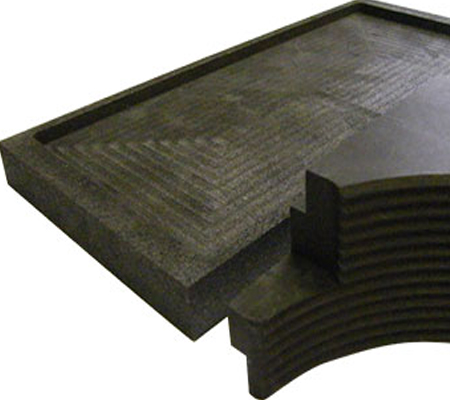

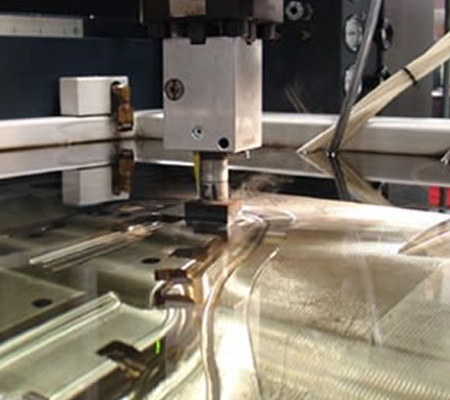

Olmec Advanced Materials Ltd has become increasingly involved in the production of graphite electrodes important in Electrical Discharge Machinery (EDM) at our graphite machining workshop in Garstang.

Unsure which grade is right for your application?

Read more about our TDX range here:

Why use graphite for EDM?

Graphite is being widely used in EDM mould making because of the following key advantages:

- Due to low wear it is time and cost effective

- Easier machining with less complex milling tools

- Perfect for high quality surface finishes and provides a high metal removal rate

- It does not melt but sublimes (turns from a solid to a gas) at very high temperatures of 3400 ºC

- It is five time less dense than Copper which means lighter electrodes

- It is very resistant to thermal shock and can withstand high temperatures

Graphite grades and EDM

As graphite has become more affordable, EDM machining shops will often use two or even three main grades of graphite. These include:

- Large grain graphite (about 20 µm) with low densities (1.76 g/cm3)

- Fine grain graphite (~10 µm) of high density (1.82 g/cm3)

- Very fine grain graphite (~4 µm) with densities greater than 1.86 g/dm3

Larger grained graphite is used for machining in roughing modes while fine grain graphites produce the best surface finish. Why use different grades for different jobs? The difference in grade makes the properties of graphite differ. Here are a few different physical properties of graphite that exhibit some effect on performance in EDM operations:

Graphite Density

As the density of graphite is increased the wear of rate and surface finish improves. Although it is recommended to use dense graphites to machine parts where geometry is critical if you want material removal it is better to use less dense graphite.

Graphite Grain Size

With very fine graphites the surface finish improves and the wear decreases. The only downside to finer graphites is material removal is less and prices increase.

Graphite Flexural Strength

The higher the flexural strength, the lower the wear and the easier it is to machine in fine detail.

Graphite Hardness

The higher the graphite hardness, the more difficult it is to machine the electrode.