Graphites for Sintering

Sintering is the process used to form shaped metals, ceramics and plastics by using heat and/or pressure without melting it to the point of liquefaction. The basic theory behind it can be observed when ice cubes in a glass of water stick to each other. There are many benefits to using Olmec Advanced Materials graphites for sintering.

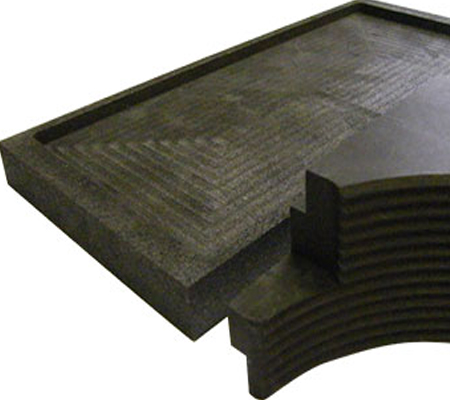

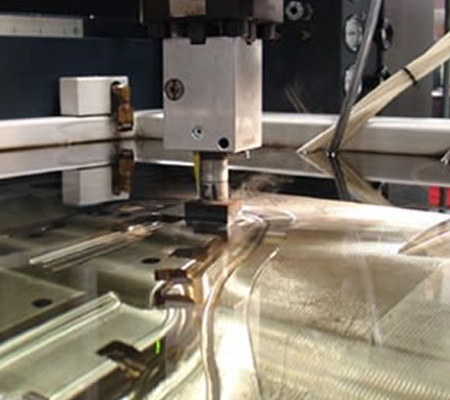

Olmec Advanced Materials Ltd supply graphites for sintering. Graphite is used throughout the pressure sintering industry for the production of graphite moulds. Our isostatically moulded graphite provides superb performance in extreme heat and pressure environments used in the sintering process.

There are many advantages of using Olmec Advanced Materials Ltd graphite in the sintering process. These include:

- Low-cost graphite

- Fast heating-cooling cycle of graphite

- Excellent temperature and pressure control at all temperature ranges

- High mechanical strength of our graphite

What grade of graphite do you need when using graphites for sintering?

Understanding changes in the coefficient of thermal expansion is very important when designing a sintering mould. Our grades offer remarkable stability and have been studied over a wide range of temperatures.

The material used to manufacture a sintering mould is selected based on the process temperature and pressure requirements. Some of our grades are selected when the material’s electrical and thermal conductivity are the prioritised parameters in order to reduce cycle time. However, when the process pressure is too high, the mechanical strength of the mould is prioritised.

Our in-house team of experts are at your disposal to discuss the best grades to suit your specific needs.