Manufacturing Process of Synthetic Graphites

Synthetic (artificial) graphite is a petroleum-based composite used in a variety of applications requiring superior to natural graphite properties.

Synthetic graphite can be produced in several ways at our graphite machining workshop, all of which change the physical properties of the final graphite. With slight changes to the manufacturing process you can create a diverse range of graphite making it useful in a wide variety of applications.

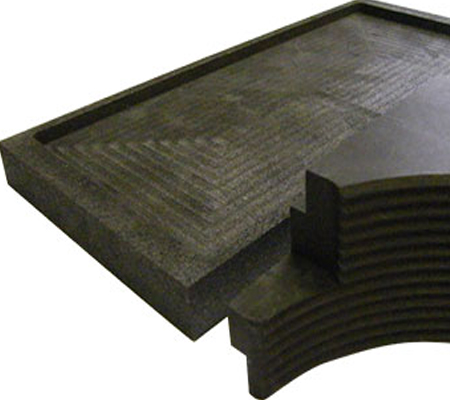

High-quality Isostatic Graphite

The strongest synthetic graphites are manufactured using a process called Hot Isostatic Pressing (HIP). This makes it perfect for use in solar energy applications, as well as LEDs and semiconductors, Electrical Discharge Machining (EDM), glass industry and chemicals. HIP is used to convert powder in the solid state to fully dense components, resulting in better physical properties than those achieved by traditional melting or press and sinter manufacturing technologies. HIP is a forming and densification process, using heated gas under very high pressure. Unlike mechanical force which compresses a work piece from one or two sides, isostatic pressure is applied uniformly on all sides eliminating porosity without changing its net shape.

Here is a video demonstrating the process and how it works:

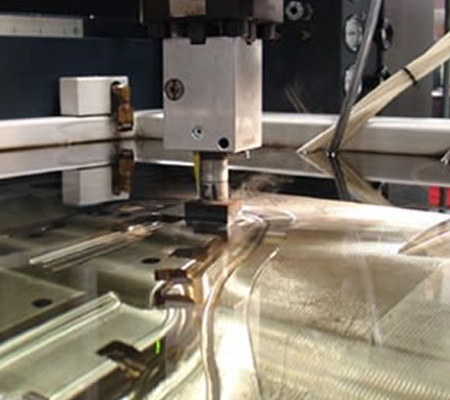

Extruded Graphite

Extrusion creates graphite that is a coarse grain. It is cheaper than isostatic graphite but still has a low electrical resistivity and excellent thermal shock resistance. It is the perfect choice for applications that do not require high strength, tight tolerances, and fine detail work. Extruded graphite is used in electrodes in furnaces for the production of recycled steel.

Vibration Moulded Graphite

Vibration moulding is a graphite moulding process that forms graphite powder into large cross-sectional shapes. Vibrating, or shaking, graphite within large containers induces compaction of the powder into a solid form. Vibration moulded graphite is primarily used to manufacture electrodes for the steel industry. Olmec do not currently offer this kind of course grain graphite.