The glass industry heavily relies on carbon graphite materials.

This is yet another industry where a close relationship with our miracle material goes unnoticed by those outside of manufacturing.

Why is carbon graphite used in glass manufacturing?

Graphite is the ideal material for glass manufacturing because it is:

-

Non-wetting.

Molten glass will stick to almost anything, but not carbon graphite. The material’s non-wetting properties mean that it is utilised when coming into contact with the molten glass without any adherence.

2. Non-scratching.

The delicate nature of glass requires gentle handling to avoid being scratched. Because graphite is inherently soft, it is the ideal material.

3. Lubricating.

Carbon graphite is a lubricating material often used as a deliberately wearing part in machinery. This means there is no need for oil or other lubricants.

4. High Thermal Conductivity

Graphite has high levels of thermal conductivity, meaning that heat travels quickly through it. Like a chameleon changing colour to match it’s surroundings, the graphite changes temperature and avoids the risk of the glass being subject to temperature shock.

5. High Oxidisation Resistance

Graphite can withstand extended exposure to high temperatures.

Where is graphite used in glass production?

The glass industry uses carbon graphite in many ways, but where?

It can be used in all sorts of roles throughout the glass industry, including but not limited to:

-

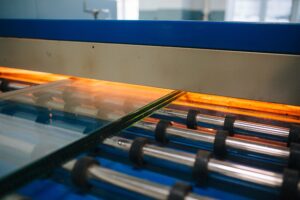

Bearings

-

Rods

-

Rollers

-

Moulds

In fact, graphite isn’t just used in sheet glass production. Many artists who blow handmade glass creations use graphite tongs to handle their work, and it can be used in annealed, tempered, or shaped glass production.

Contact Us for more information about our carbon graphite grades.